PCB design and fabrication

Digital IC design and vlsi notes

PCB design and fabrication

- Source this playlist on Testing.

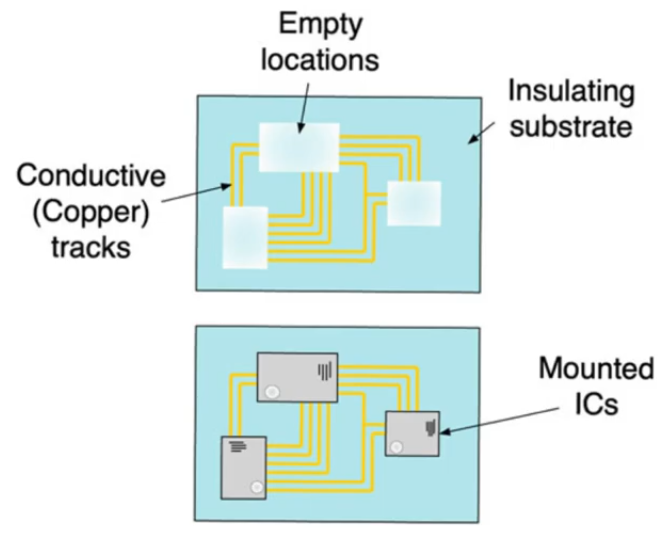

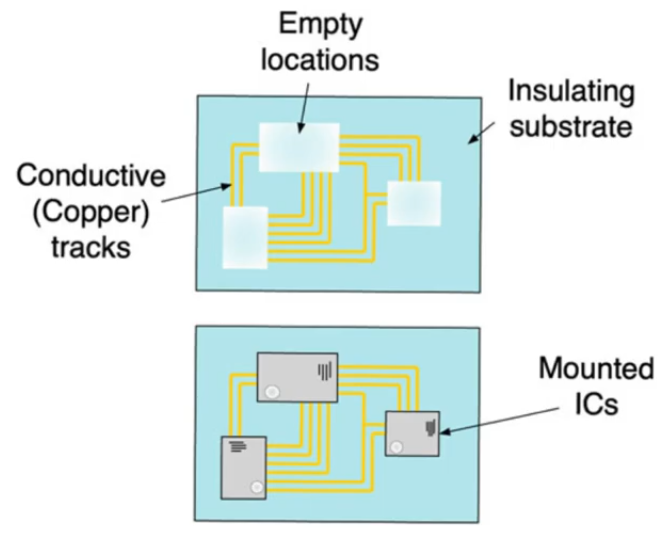

PCB

- Printed circuit board

- It’s the most likely platform upon which independent microchips are combined to form an overall system

- consists of an insulator substrate (plastic/epoxy)

- provides thermal radiation

- provides mechanical support

- On top of the pcb there are tracks of conductive material (usually copper)

- provides wires that can communicate and connect the components of the system together

- On top of the pcb there are footprints that indicate locations where you expect that your chips will be installed

- copper tracks communicating between these footprints

- In the next step you perform installation of these chips in their locations

- manually if the chips are DIP or surface mount packages

- or using equipment in the case of BGAs

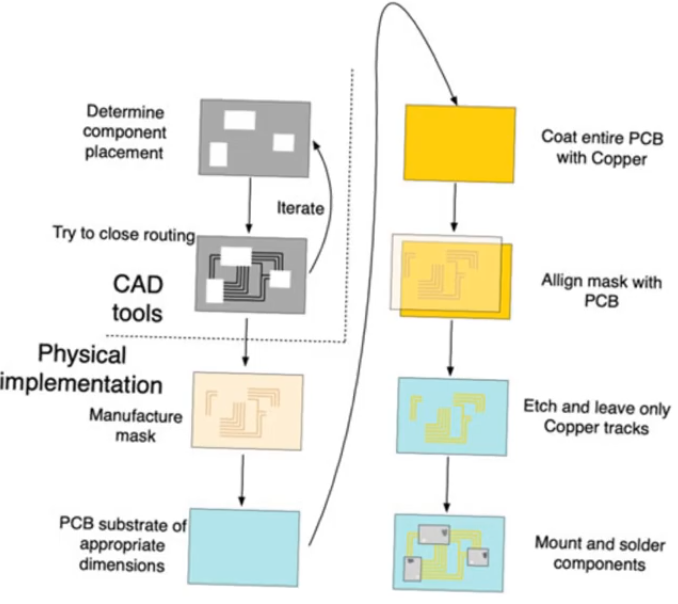

PCB Design

- There is an analogy between PCB design and microchip design

- The design tells where the copper tracks are gonna be

- The PCB itself is an insulator substrate

- All you create on top of it is the conductive copper tracks

- You have a certain amount of real estate which is the substrate

- Witin this substrate you have to distribute a number of resources your chips and passive components

- you also need to connect the input and output pins of these microchips in a specific way

- To communicate with each other or with jacks that come off the pcb

- you have to determine ways inwhich these constraints (connections between chips) are satisfied

- These copper tracks provide an additional capacitive load increasing delay

- so you may find closure (a solution that functionaly connects the chips together but it creates a situation where the delay is too much)

- In that case you try to place the chips in other locations and then do rerouting

- This reminds of placement and routing

- The design flow and optimization process is very similar

- with one difference, the pcb design is less computaionally intensive because the constrains alot more permissive

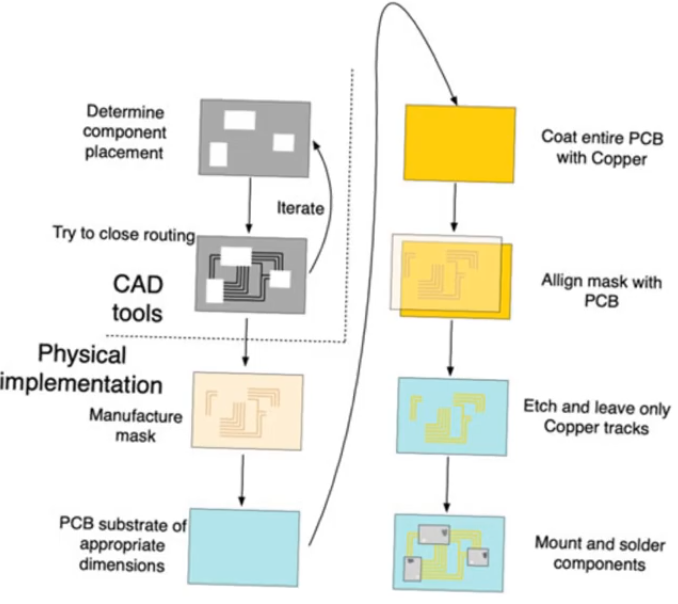

fabrication flow

- Once you have determined the routing tracks required, then go the fabrication stage

- the fabrication stage is very similar to photolithography

- we begin by placing the components and then routing between them

- then proceed to fabrication

- First step is to manufacture a mask created similary to the mask created for microchips

- except in this case the mask is usually formed of solid material

- the copper tracks are itched on the mask as openings

- The mask and the substrate are gonna be roughly the same size

- Then you coat the entire pcb with copper

- align the mask with the pcb and use an itchent to each throguh the exposed parts and leave the unexposed parts

- then mount and solder the components

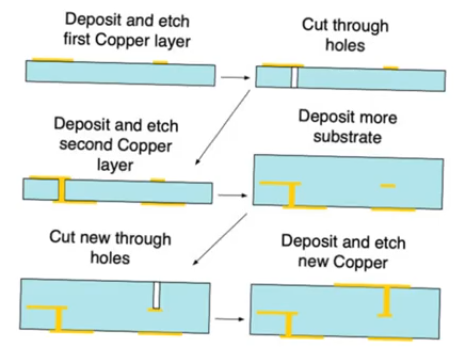

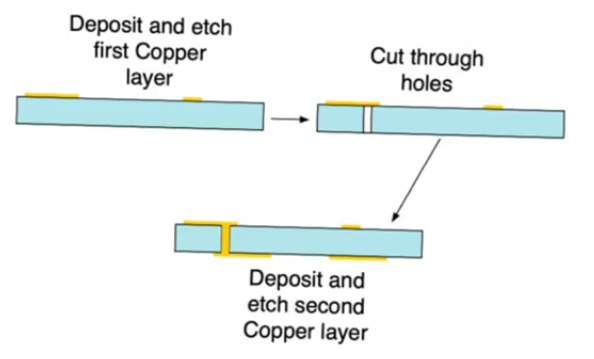

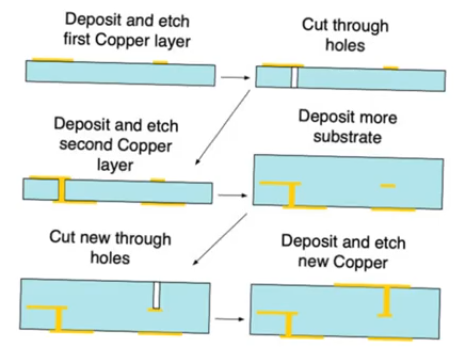

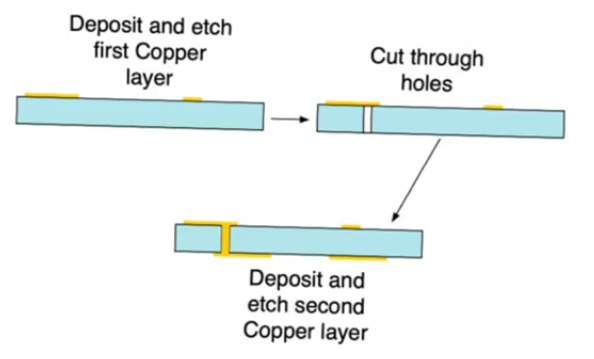

Multi layer

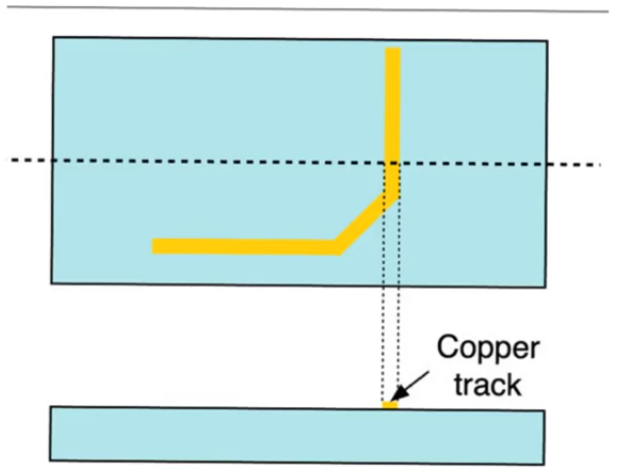

- when you fail to find a colsure for routing on a pcb, you will need another layer of metal wire to create crossovers

- this is similar to the need for multiple metal layer in asics

- This is difficult in dip chips because they go through holes in pcb occupying both sides

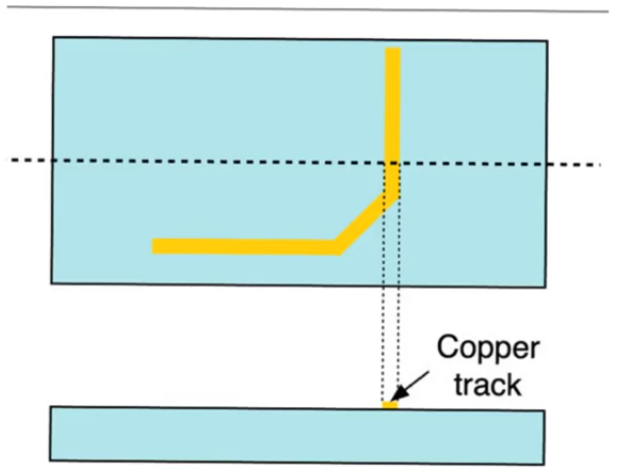

- These two layer are gonna need to communicate

- this is created similar to vias in mircochips, you cut holes through the pcb, then when you deposite your copper these holes are filled simultaneously

- some pcbs require more than two layers

- you create the first layer of metal wires and cut the holes,

- then the second layer, and then you deposite insulator on top of the second layer, then you create via 2, then the third metal layer

- this is agian similar to the mircochip fabrication process