Defects, faults and errors

Digital IC design and vlsi notes

Defects, faults and errors

- Source this playlist on Testing.

Terminology

- DFT uses alot of terminology,

- some of the words have colloquial uses that are very similar

- but they mean different things in DFT

Testing and Verification

- Testing refers to making sure that a finished chip is working

- Testing usually applied to finished products (fabricated chips)

- this could apply to a prototype, FPGA, research chip

- it’s usually refers to a chip that is shipped for commercial use

- It’s testing the design in a hardware platform,

- if the product is destined for an FPGA, testing the design when it’s actually burnt on the FPGA

- Verification is about the design, you verify the design not the finished product

- Any kind of testing before fabricating the chip is considered fabrication

- All the simulation at whatever level are considered fabication

- Testing usually applied on a per chip basis, evrey chip has to be tested before it’s shipped

- Verification has to be done for the design and it’s done once, but the test is done for every finished product

- If your ultimate platform is an ASIC and you use an FPGA first to test the functionality for example, then using the FPGA to check first is part of verification

- It’s much cheaper to do verification than to do testing

- So you need to expand as much effort as you can into making sure that your design will work once it’s fabricated

Defect, fault, and error

- They describe pretty much the same thing at different levels of abstraction

- A defect is an actual physical problem that happens when we fabricate a chip

- A fault is one way in which we can model this defect at a certain level of abstraction

- An error is an observation that you make when you perform a test that exposes the uderlying fault and defect

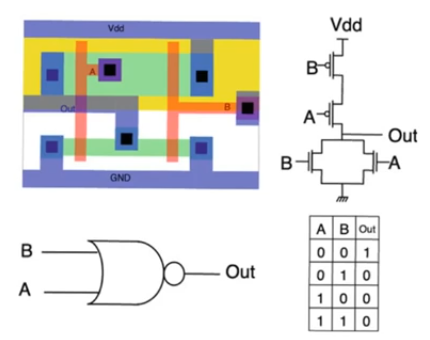

Example

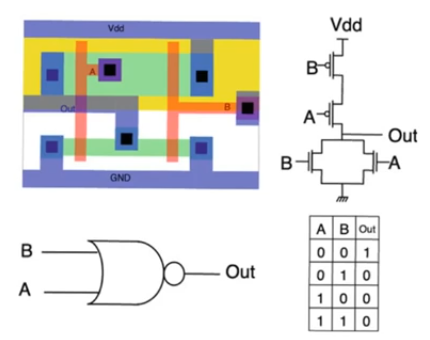

- standard cell entry for a two input nor gate

- layout

- circuit level model (delay, power information)

- logical model

- truth table model

- each of these entries represents a different level of abstraction

- Defects are physical problems, they are the root cause of everything has to be done in DFT

- CMOS fabrication is a very long process and alot of things that can go wrong when applying photolithography

- All of these issues can lead to physically realised problems and deviations on the chip

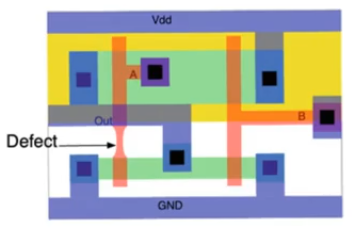

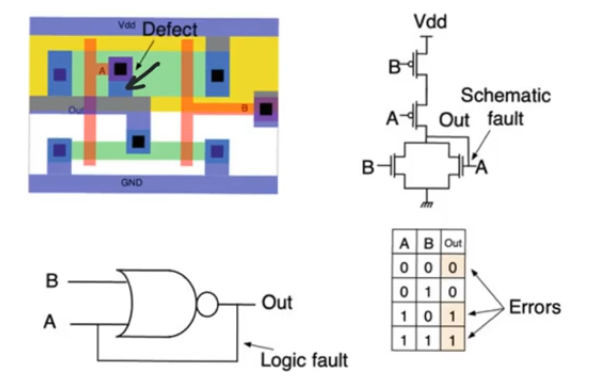

- Assume we have a problem in the layout that leads to a short circuit

- due to misalignment or wrong etching, or overdiposition of metal, or other reason

- this pyhsical manifestation of the problem is called a defect

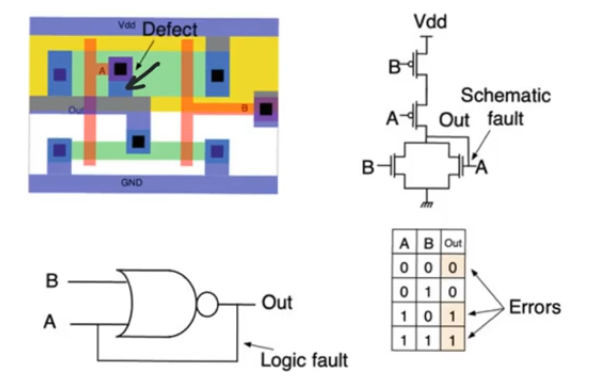

- A fault model is one way in which we can model this defect at a certain level of abstraction

- There can be different faults that results from the defect

- At the circuit level this over metal deposition can be modeled as a short circuit between the drain and the gate of a transistor (output and input A)

- A schematic fault model of this defect

- It can be modeled at the logic level as the short circuit of between input A and output of the gate

- This is a different fault model for the same defect

- Which model is used for the fault depends on the kind of fault that happened

- An error is a deviation from the gold standard that you see as an observation of a defect

- In the example when the input is (0,0) a 1 should be observed, seeing 0 at the output is an error

- this error indicates that there is a defect underlying this and that this defect can be modeled in one of different ways using the fault models

- Certain defects can manifest themselves in certain fault modeling levels but not in others

- consider the example’s defect that is due to under deposition or over itching of polysilicon that leads to thinner polysilicon line at a certain location

- If the logic level is used to model this fault then it’s impossible to model it (you’ll have the same logic gate as the correct one)

- because there is no tools at this abstraction level to model what’s happened here

- no errors won’t be observed

- On the other hand if the circuit level is used to model this fault then you’ll observe certain errors

- because the narrowed polysilicon line will have a higher resistance than expected

- so perhaps you’ll see a delay performance that is worse than expected

- so the circuit model can expose this defect into a fault that can reflect into performance