Static Timing analysis

- source this tutorial on static timing analysis

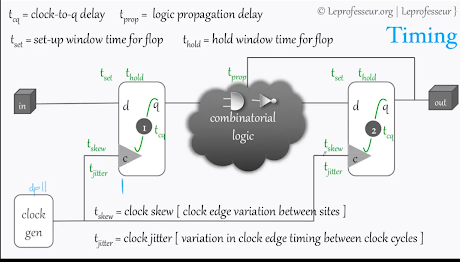

hold and setup time

- setup time is associated with the clock

- hold time is associated with the data

- if hold time isn’t satisfied (violated) insert buffers

- hold time violations must be fixed

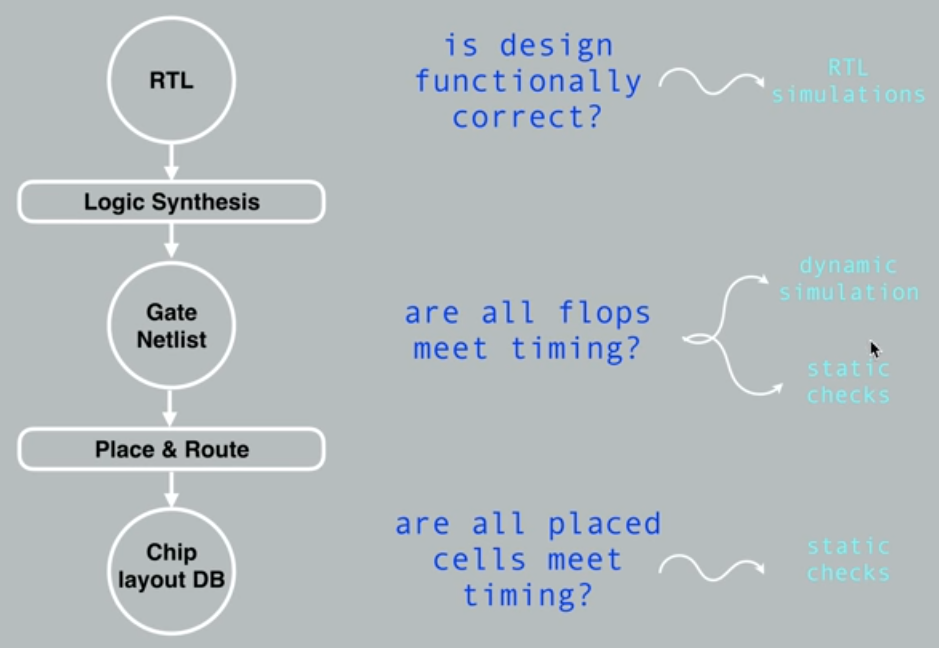

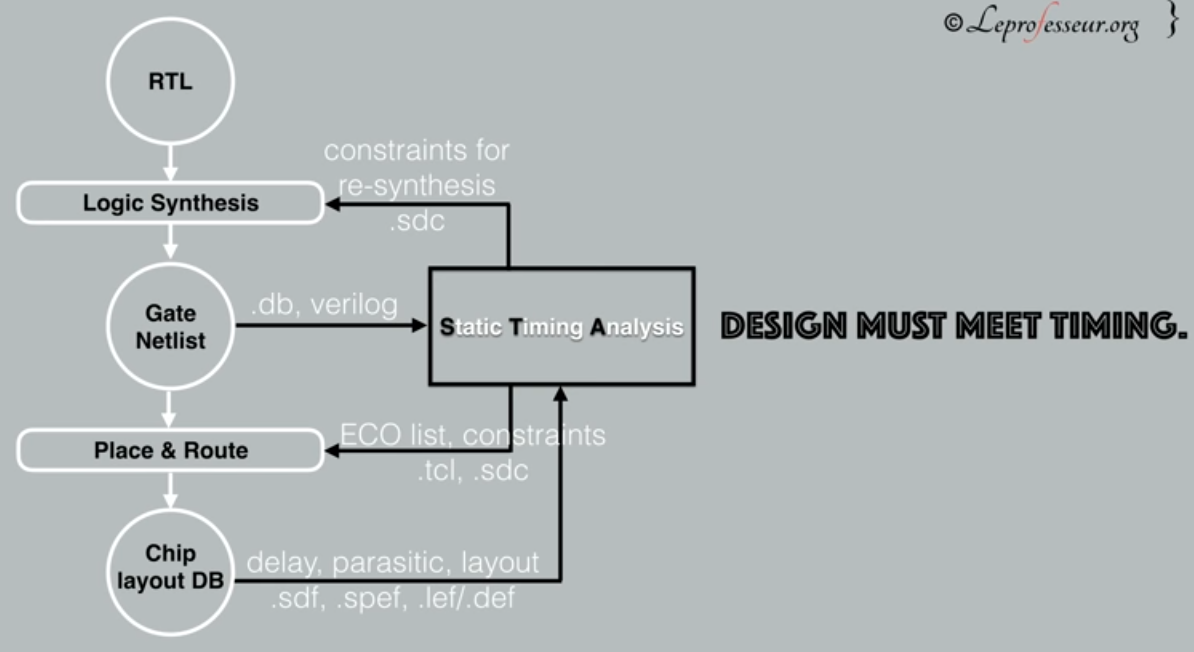

Detecting problems in design flow

static timing analysis

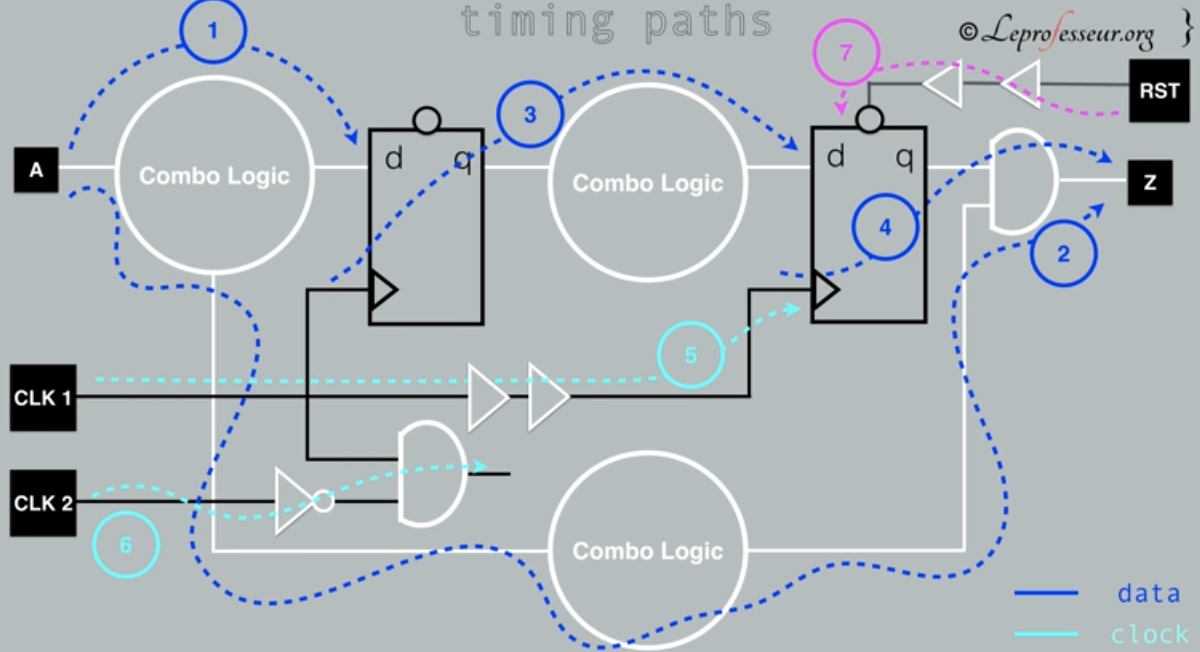

- Timing Paths

- Blue: data path 1,2 Asynchronized, 3 synchronized

- Crayn: clock path (clock with combinational logic)

- violet : reset path

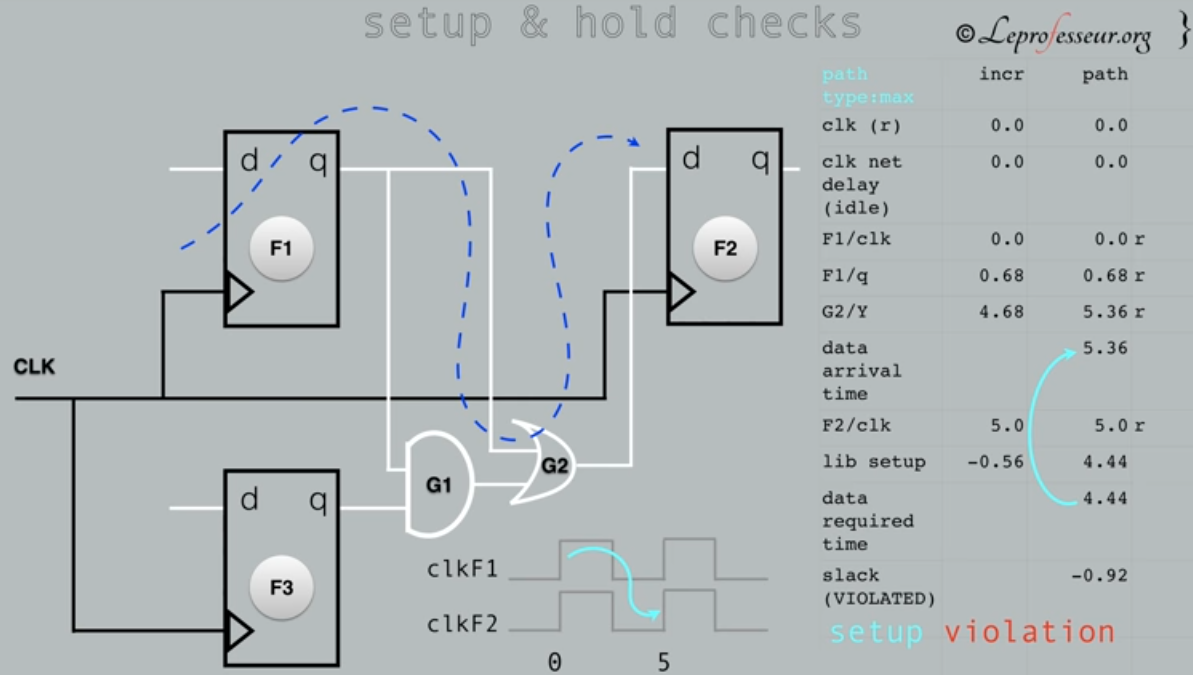

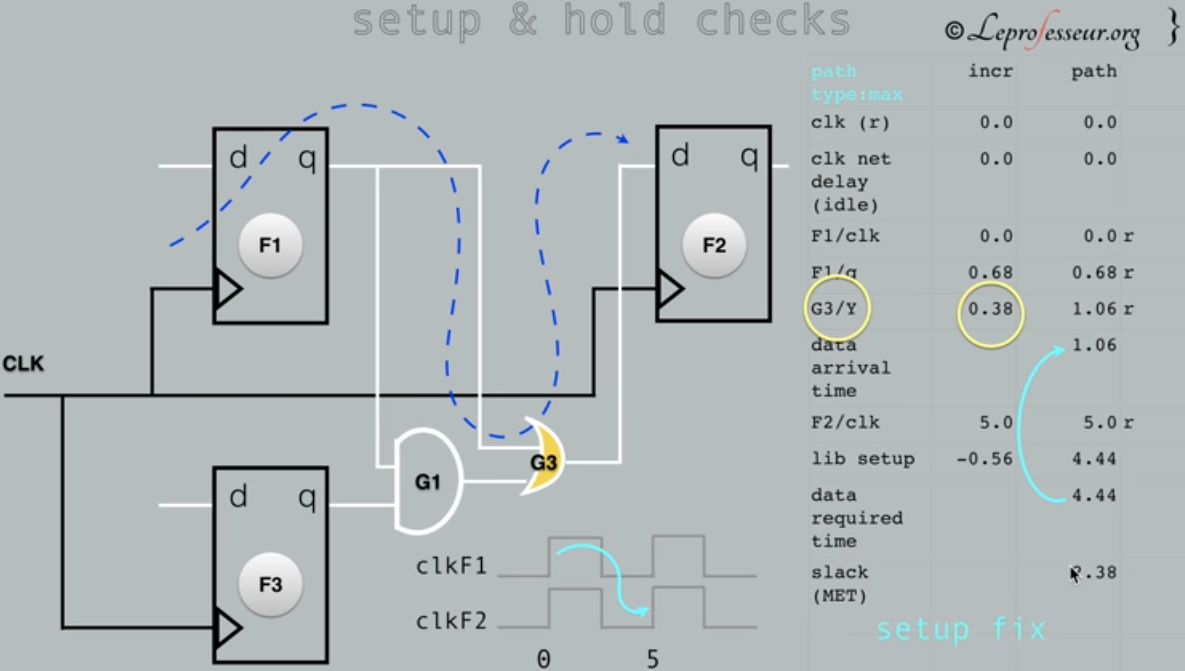

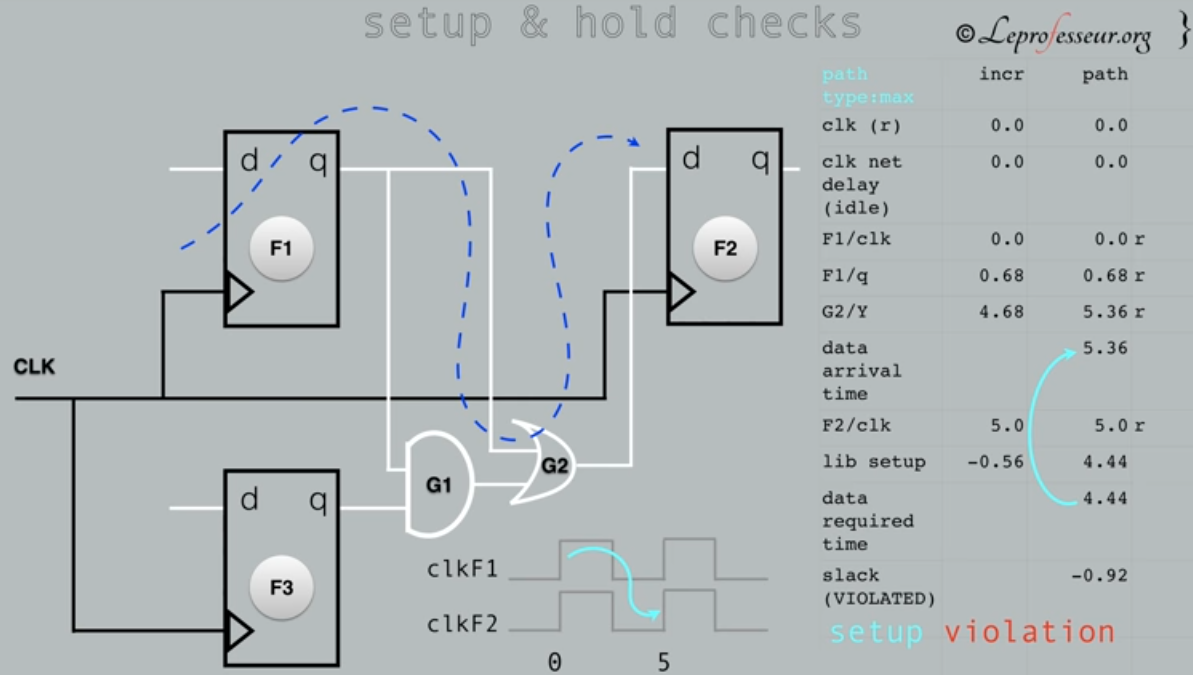

Example

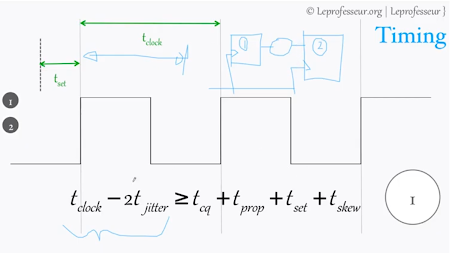

1) Setup Time (max delays)

- Clk delays = 0,

- FF1 propagation delay =0.68 (for d to get to q it needs 0.68time) ->total path till now d->q=0.68

- G2 propagation delay=4.68(from i/p start to get result)-> total path till now=4.68+0.68=5.36

- So input at FF2 d will arrive at 5.36 time,

- F2clock arrives at 5, and its setup time(time required for the input to be present before the clock) is -0.56 (input should be present before the clock arrives by0.56),

- So input at d should be present at 5-0.56=4.44

- But it is present at 5.36, so we have setup time violation (slack) by 4.44-5.36=-0.92

Solution:

1- setup time violations associated with the clock, so we can increase F2 clock time 2- change G2 cell, it takes most of the time, replace it with another cell with less max delay

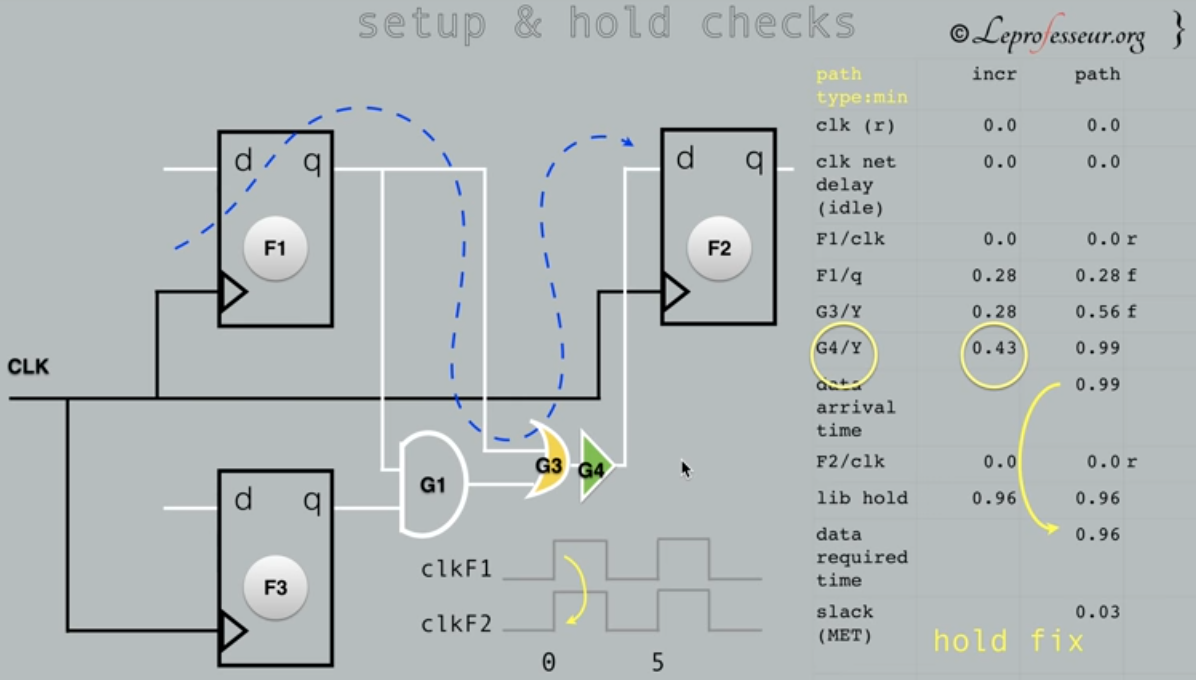

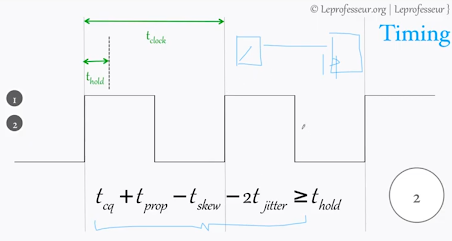

2)Hold Time(min delays)

- FF1 minimum time d->q, (minimum possible time for the data to change)=0.28

- G2 minimum time i/p->Y,=0.28 ->total minimum path time till now=0.56

- So data at FF2 input minimum hold time required = 0.96

- But minimum possible arrival time (minimum time data could change in) is 0.56

- So we have a hold time violation

Solution:

- Add a buffer to add more delays at the FF2 input

- But this may corrupt setup time check so do it again and repeat

- Then do equivalence and functional checks again and repeat