Boundry scan and JTAG

Digital IC design and vlsi notes

Boundry scan and JTAG

- Source this playlist on Testing.

Introduction

- JTAG (Joint Test Action Group) is an IEEE standard used to allow designers to use the BST (Boundry scan technique)

- BST is a technique that allows us to probe pin values of chips installed on pcbs without having to use physical probes

- This is analogous to a topic within DFT in microchips

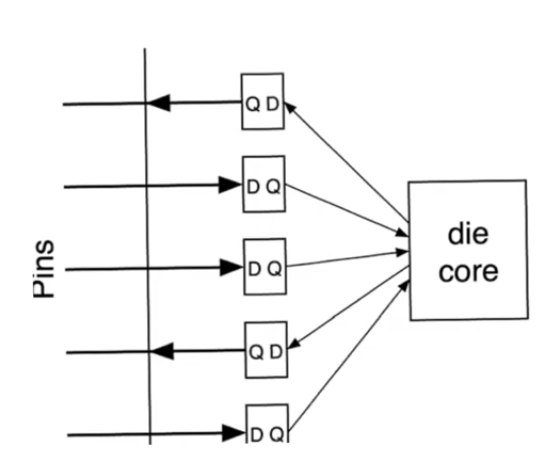

Chip boundry

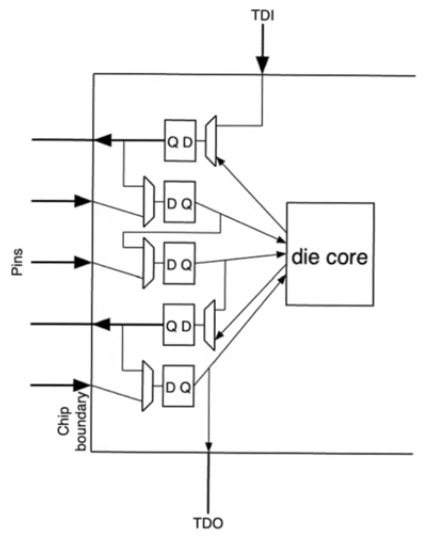

- Within the IC package there are the chip’s inputs and outputs connected to registers contained within the die

- used to register the values of the pins before they are presented to die or pcb

- These registers would allow communication in parallel

BST

- The boundry scan technique requires us to modify every input and output register in the chip into boundry scan register

- The BST is a scaling up of the scan technique from the chip level to the pcb level

- While most embedded systems designers wouldn’t have to deal with scan technique, they would have to understand the BST

- The two aren’t mutually exclusive,

- you can have the scan technique enabled on the chip

- and BST enable on the PCB and the two aid each other

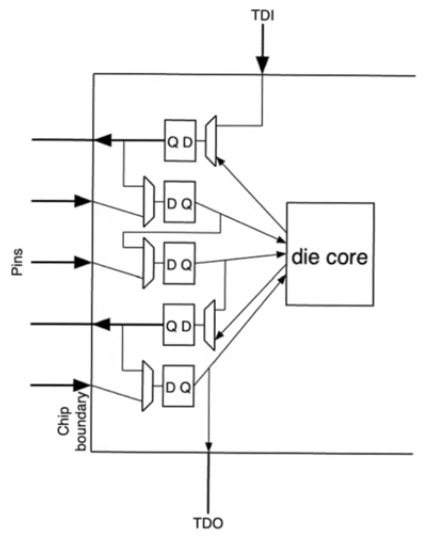

- The first step is to modify every register into a BST register

- All registers will have an additional multiplexer

- The Mux will feed the

D input of the register either a normal input, or a test input

- The test data input

TDI is different from the TDI in the scan technique

- same for the select

Test input pin that sets the multiplexers in test mode or normal operation mode

- In test mode operation is similar to scan technique,

- the first register will accept the

TDI input

- the second register will accept the registered value (output) from the first register

- and so on till the final register that accepts the output of the previous one, and it provide it’s output to a pin called

TDO

- Test data output

TDO pin is also independent from the TDO in the scan technique

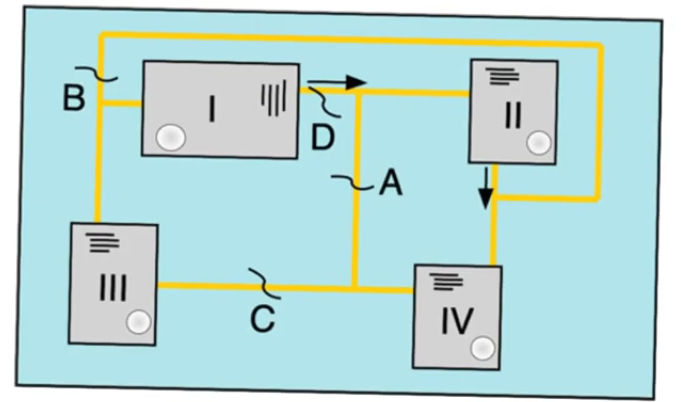

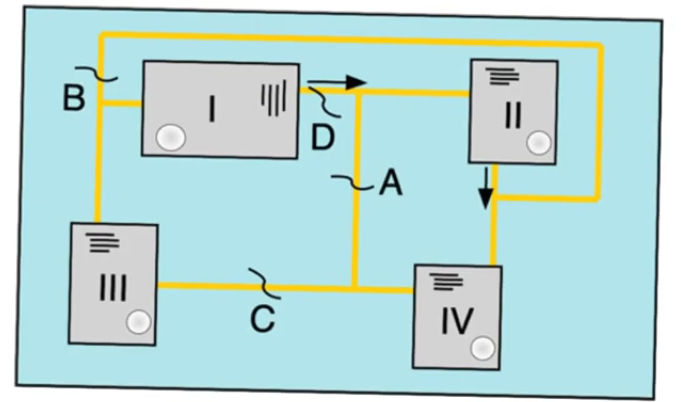

PCB setup with multiple chips

- In a pcb with multiple chips connected with (multibit) copper tracks

- All chips in the PCB are boundry scan compatible (each one have BST modifications)

- each one have

Test, TDI, TDO pins

- There is also

Test, TDI, TDO jacks on the PCB itself

- There are two sets of tracks on the PCB

- The tracks that connect the chips to each other so that they function properly and form a system with each other

- There is an indenpendant set of tracks that form a boundry around all these chips

- The other tracks starts from the

TDI jack goes to the TDI pin of the first chip

- Then exit through

TDO of the first chip

- Then the

TDI of the next one

- till it reaches the last on

- The final chip’s

TDO is connected by track to the TDO jack of the PCB

- The PCB

Test input is also distributed to the Test pin of all chips

BST Usage

- BST is useful when you create a PCB with multiple chips you don’t have mechanical access to the pins (you can’t probe them)

- specially in case of BGA packages

- This allows you to probe the values of the pins because they are all part of a shift register

- You can also force the values of a chip inputs to a specific value

- This can be combined with the scan technique to have nested levels of scanning

- BST also can be used to probe and ensure the integrity of the assembly

- you can ensure that the pins are actually connected to the copper tracks

- it’s also a way to test the pcb itself and the connection of the chips within it

- you can force the output pin of a certain chip to a certain value and then you can check that you received this value properly at the other chips

- The specific way in which you perform a test (how the test vectors are shifted from

TDI to TDO) is specified by the JTAG standard.